PLANT DESIGN PROJECT - RESOURCE RECOVERY FROM WASTEWATER TREATMENT PLANT INTO VALUE ADDED PRODUCTS

- Amar Haiqal Che Hussin

- Aug 1, 2021

- 1 min read

Updated: Nov 17, 2021

Acknowledgement

I would like to give credit and expression of gratitute to Ikmal Haziq, Lee Zee Khai, Amira Masturina and Nur Amieza for completing this plant design project together. Not to forget our supervisor, Dr. Noorfidza Yub Harun

Case Study

To put short, this project is about the feasibility of recovering materials from the wastewater and process it into value-added product. Apart from that. each members were assigned to design a major equipment involved in the plant design

Plant Design

Resource we want to recover

Methane from wastewater sludge through anaerobic digestion

Bio-oil and char from pyrolysis of sludge

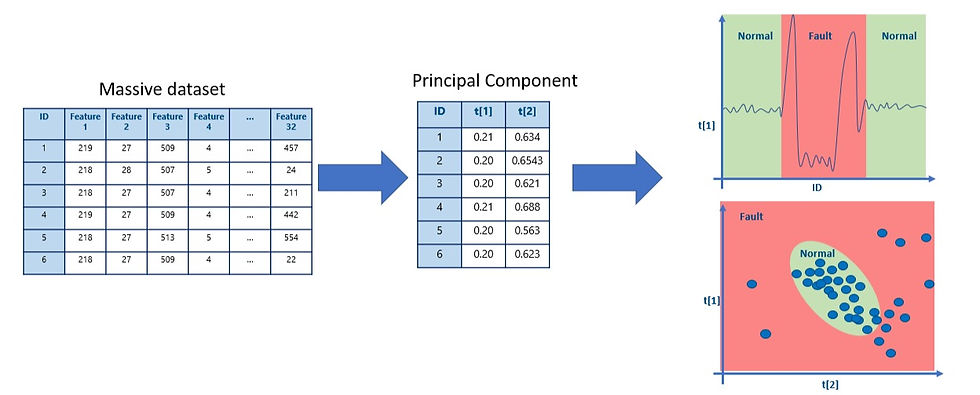

Simulation Snippet

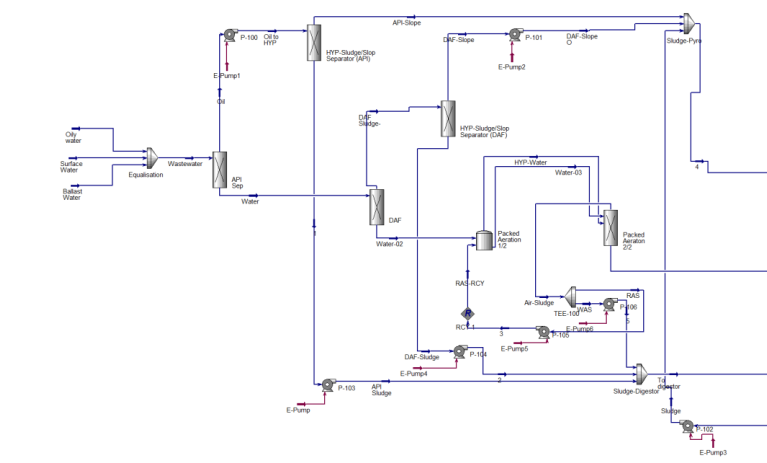

For this project, we used Aspen HYSYS for chemical plant simulation and CapdetWorks for wastewater treatment plant simulation and economic estimation. Note that simulation of wastewater in HYSYS (shown below) use multiple hypothethical component to simulate wastewater components

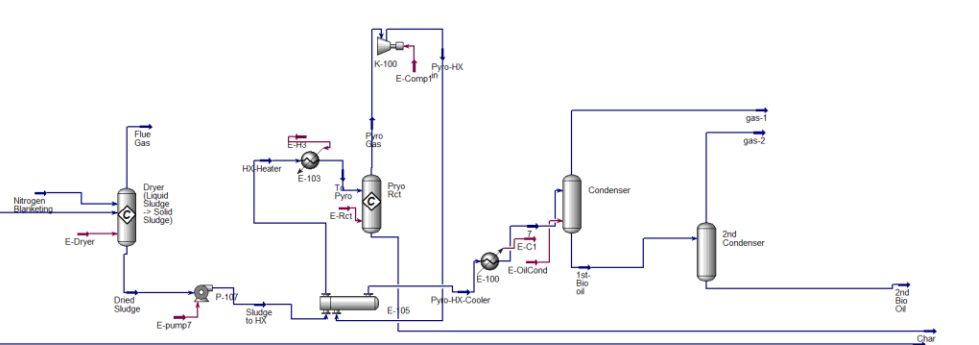

The sludge from the wastewater treatment plant goes either pyrlolysis reactor or anaerobic digestor. Pyrolysis process breaks down dried sludge to release gases and char. The gas were then condensed into bio-oil

Plant Design

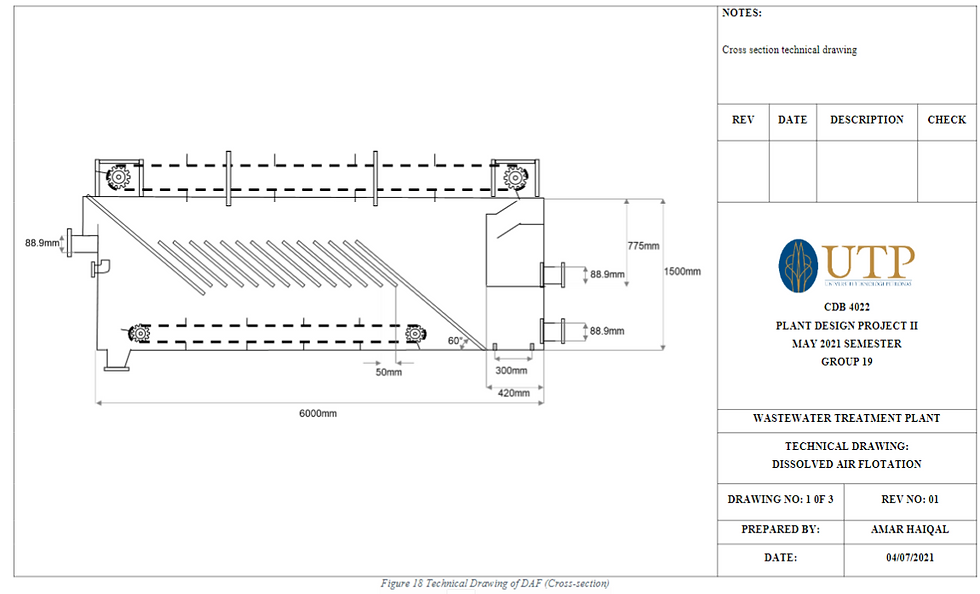

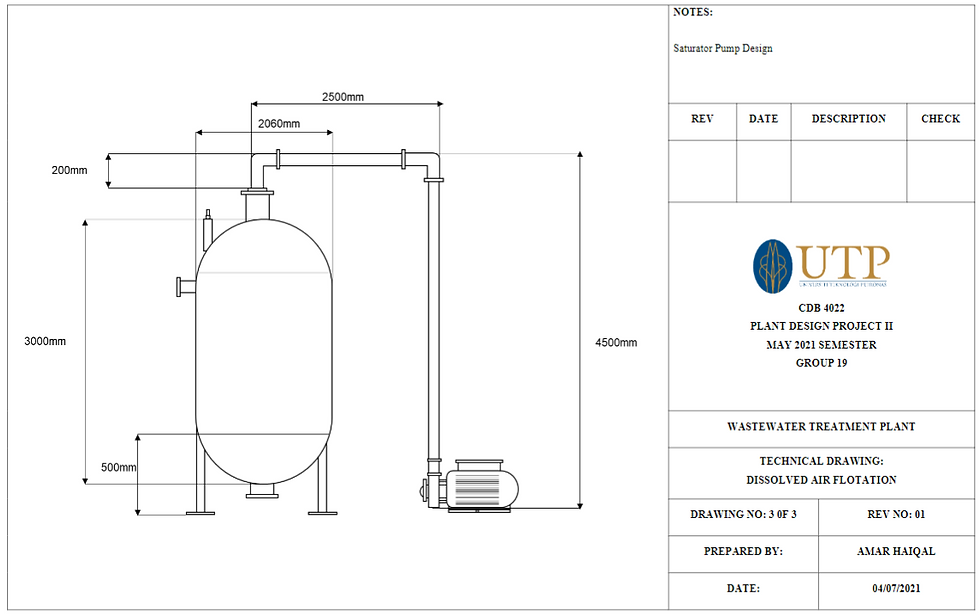

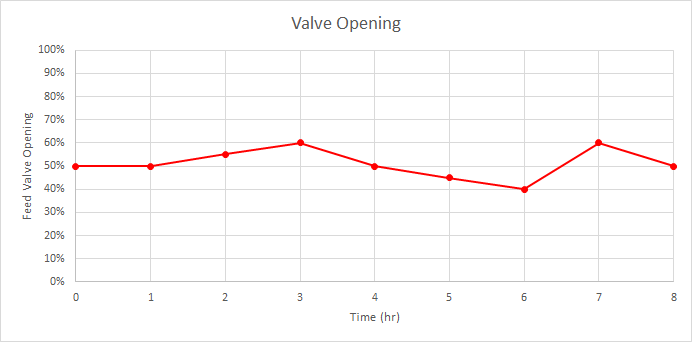

Design of Major Equipment (Dissolved Air Flotation)

Basis of Selection

Technical Drawings

Data Sheet

Economic Analysis

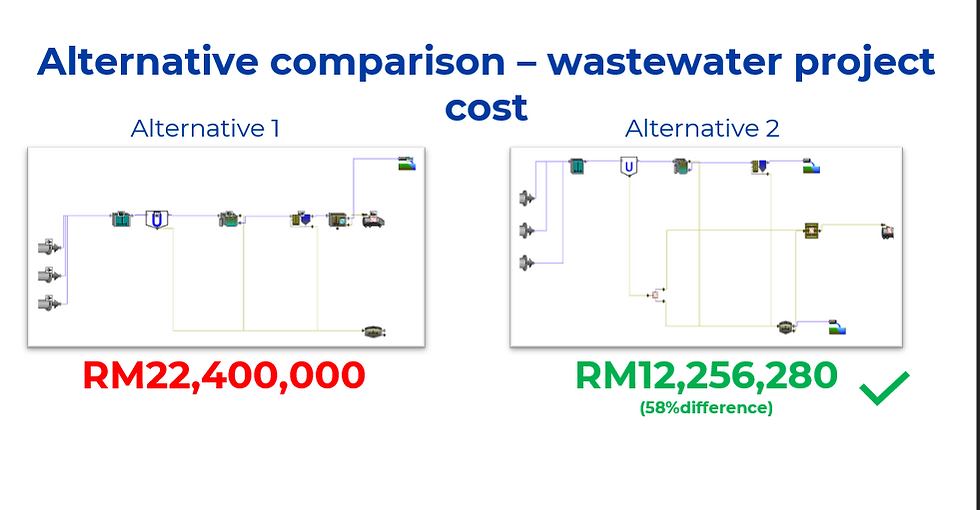

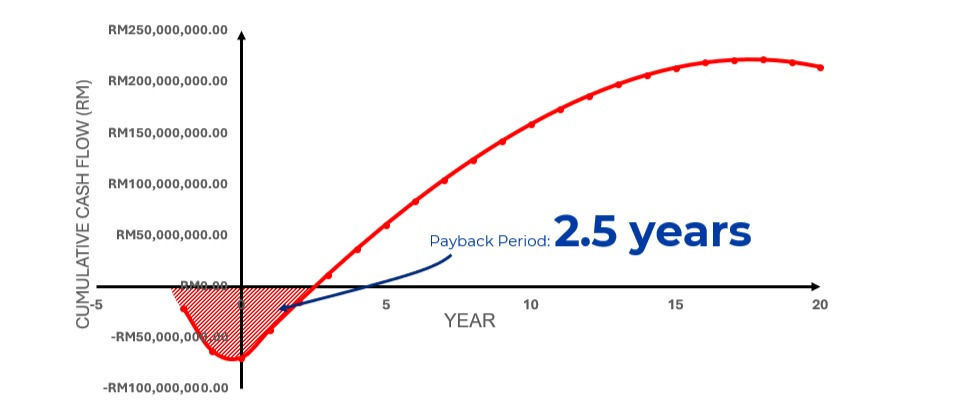

Preliminary Wastewater Treatment Plant Economic Analysis

The estimated cost and the wastewater design were done in CapdetWorks

Economic Assumptions

3 years of construction, 15 years of operation

24/7 operation all year

Constant annual revenue

OPEX increment +5%/year

Income Tax = 24% Net Profit

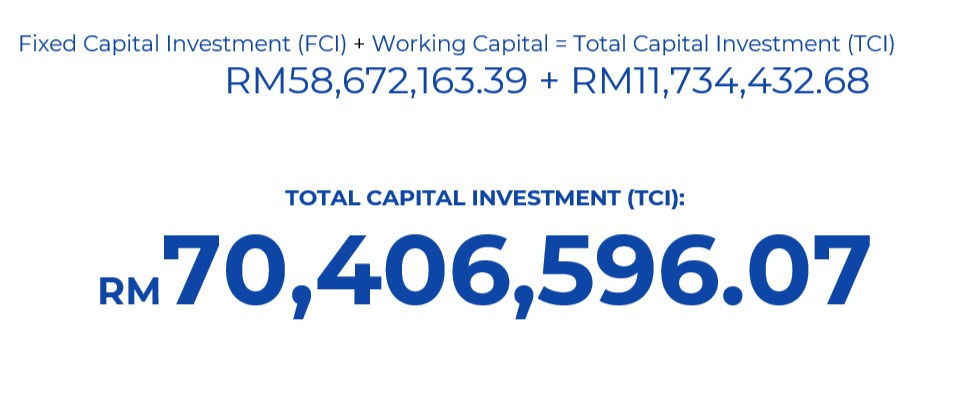

Capital Expenditure

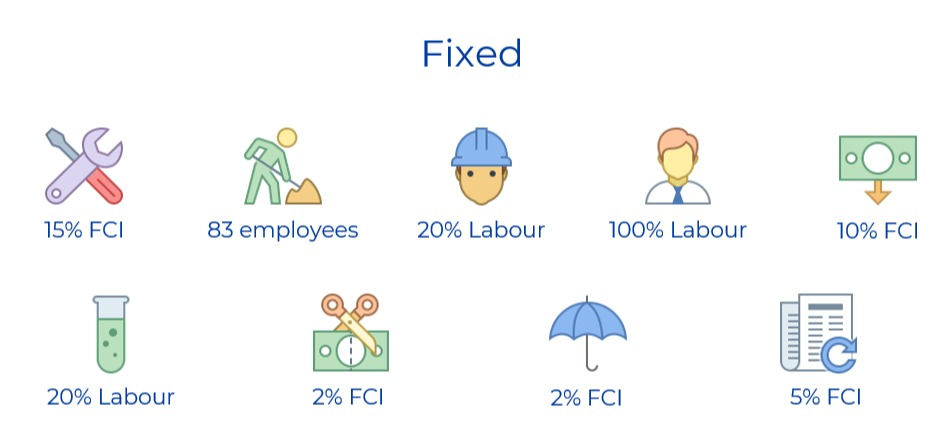

Operating Expenditure

Economics Evaluation

Comments